Introduction

From a practical standpoint, many libraries already offer innovative educational technologies through Makerspaces, but training for instructional faculty who use these resources within these spaces continues to be difficult, not only due to the informal nature of the spaces, but also because successful use of these technologies and services often relies on part-time student employees, untrained library personnel, and or online resources for their training (Moorefield-Lang 2015). One specific example of technology found within Makerspaces that may need specialized training is 3D printing, or the process of making a physical object from a three-dimensional digital model, typically by laying down many thin layers of a material in succession.

With respect to this innovation, instructional designers and technologists within libraries are already aware of the importance of this technology as it has repeatedly found its way to the top of emerging educational innovations in higher education publications such as NMC Horizon Report (2013) and Educause Review (2014) over the last five years. Keeping in line with trends in higher education, libraries have been successfully supporting informal student learning of 3D printing; however, anecdotally we have noticed that even though access to the technology has been offered, it has yet to be widely adopted in the formal curriculum.

The mission of James Madison University is to grow as an academic community committed to preparing students to be educated and enlightened citizens who lead productive and meaningful lives. Strategically, the university has identified a number of dimensions to meet that mission. Specifically, the university has focused on engagement at a variety of levels to challenge and support students, faculty, staff, and alumni through meaningful engagement with the university, community, and the world. Engagement in these terms enhances academic, personal, and professional learning while reinforcing community service, civic engagement, and ethical decision-making. The Libraries, as a hub of engagement and learning at the university, focus not only on providing support and resources focused on scholarship but also on supporting innovative instructional practices through the instructional design and technology team that is tasked with encouraging university faculty to adopt instructional methods and practices that may be out of their immediate comfort level. Teams like these focus on providing programming that contributes to an academic community that is committed to academic rigor and teaching excellence, combined with the intentional engagement of students and faculty in meaningful research and experiences and other scholarly endeavors. The result of this allows faculty within the library to create experiences that focus our academic pursuits on solving ill-defined instructional problems that tend to nestle our research within the framework of educational design research (McKenney and Reeves 2008).

For several years, the Libraries had been offering workshops that taught faculty members how to begin using 3D printing. These workshops began with only a few 3D printers in a format defined as sandboxes where faculty could come and explore the topic with limited direct instruction based on the ideals for the community of practice. As with each new development within education technology, stakeholders often find developing a familiarity with the technology is necessary before they can use that technology with their students. Historically, libraries often provide service as the location when new technology is not widely available, either due to cost or at times due to the amount of support or training required to successfully use that new technology. As we began to realize the increasing interest in the technology for teaching and learning, we also began to develop a classroom known as 3SPACE that was created specifically for instructors interested in guiding their own students through the 3D printing process. Unlike instruction in preK-12, the situation for most instructors in higher education is that faculty do not “own” their classroom so most faculty do not have the opportunity to develop a deep understanding of the technology outside of their time within the specialized classroom. It occurred to the instructional design team that the adoption of 3D printers could potentially mirror the adoption of printers that occurred in the early to late 1990’s where paper printers were first housed in libraries until costs dropped and availability increased, making it possible for most faculty and students to have that type of technology in their dorms and/or homes.

To help reduce the time for adoption, we began to envision a series of workshops where we could begin to give 3D printers to faculty so that they would increase their own familiarity with the technology while also building a community of inquiry with colleagues from across the university. Coincidentally, while we were considering this, a local pre-K–12 school system invited us to their own professional development workshop where we encountered 3D printer kits where faculty could build their own 3D printers. After attending this workshop, we conceptualized a series of our own workshops where we would guide faculty through the building of their own 3D printers to create ownership of the learning process while encouraging them both to gain familiarity with the innovation and to help encourage the diffusion of this technology from the existing hub of the library to individual home departments. We envisioned a workshop that would guide learners through the Learning Circle of Reflection, Learning, Planning, and Action. Thus, we developed weekly workshops that followed these steps in terms of how faculty might use their new printers within their own classrooms.

Participants for the workshop were faculty recruited from across campus. The inaugural class included five faculty members and a graduate student from each of the following disciplines: literacy education, science education, occupational therapy, and media arts and design. The participants applied and were accepted in the university’s Build Your Own 3D Printer five-week immersive experience. In teams of two, participants built their own 3D printer and explored ways 3D printing might be integrated into their assignments, courses, or research. The first two weeks focused on collaboratively building a Jellybox 3D printer. The following two weeks focused on printing and designing 3D objects as a way to create instructional activities with students. The last week included printing artifacts, and teams were awarded their own Jellybox 3D printer.

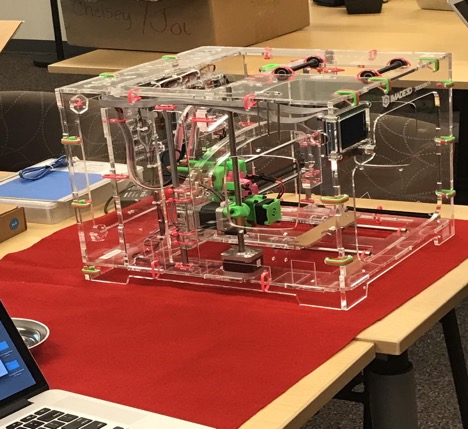

Jellybox 3D Printer: An Overview

The Jellybox 3D printer is made by IMADE3D. This company’s philosophy is that there is no better way to learn 3D printing in depth than to build your own machine. Our experience building a Jellybox 3D printer helped to bring this point home, as we did in fact have a more comprehensive view of how a 3D printer operates after building one, even with our extensive prior knowledge of 3D printing. Our choice to use this particular printer came about after a local elementary school challenge teacher reached out to a few of our team members and invited us to a day-long workshop to help them build their own Jellybox 3D printer. They had invited IMADE3D to lead the workshop and walk us through how to build and operate the 3D printers. This was made possible because they are located in Vienna, Virginia, close to our university campus. Upon completion of the workshop, our team reflected on the experience and decided to purchase a kit for our entire team to assemble. One of the challenges we experienced building our own was not setting aside an entire day dedicated to building the 3D printer. However, our printer build took much longer than anticipated, in the face of short build periods, with participation starting strong at the outset but slowly dropping off as schedules became busier. Eventually, our 3D printer did get assembled, sparking an idea how we could possibly work with faculty to build their own 3D printers that they would then be able to bring to their departments for use in their courses.

Our experience tells us that building the 3D printer helped us deepen our understanding of 3D printing and that this build could be completed either all at once in an 8-hour day or with smaller chunks of time over the course of a few weeks. We also noticed that collaborating together really helped us feel ownership: understanding and using the 3D printer and having others to bounce ideas off of. Some of our initial fears where we thought we might break a 3D printer were put to rest because we knew where every little screw, bolt, and zip tie went, and what held it all together. Our confidence grew knowing that some of the pieces were 3D printed and replacement parts could be printed in house allowing us to be able to fix our own printer if needed. We brainstormed an immersive experience where faculty would commit to five sessions designed for them to have extended time and space to build the 3D printer, and then have time to design and print objects. All participants were required to identify a building partner from their department to ensure no one would have to go back as the sole point of contact for how to operate the 3D printer.

We discussed the idea of the partners having more ownership by taking the 3D printer back to their department after having put it together as a team. We chose the Jellybox Easy Build kit primarily because it was designed for novices and teachers among other groups as listed on the IMADE3D website. The cost is $990.00 for the easy build kit with funds made available as a part of our sandbox budget, where money is set aside each year to get instructional technologies into the hands of faculty through our various programs and events.

The library ordered a Jellybox Easy Build Kit for each group. As a whole group, we watched the step-by-step videos and assembled our 3D printers together. Initially, we planned to complete the builds in two weeks and found that more time was needed to complete the build in this timeline. We met for five consecutive Fridays from 9:00 am to 12:00 pm. Because of this elongated timeline, participants did not have as much time to print or to reflect together on the experience.

Afterwards, we collected information from the faculty participants about their experiences with the 3D printing workshop. We asked:

- What was your experience with 3D printers prior to this workshop?

- Describe your experience in the 3D printing workshop and what new insights were gained?

- How do you envision using your 3D printer in your teaching and/or research?

- Have there been any collaborations with fellow workshop attendees? Describe.

Faculty Experiences

Even though not a requirement, all six participants had reported in their application for the program that they completed a 3D printing or maker related workshop prior to attending the Build Your Own 3D Printer program. Because of the background knowledge the participants already had, they were able to think more deeply about how the parts worked and could more easily realize when something was off. One media arts and design faculty members added that it “gave a sense of being able to troubleshoot issues and understand limitations/perimeters.” All indicated they had classroom projects in their departments for which they planned to use their 3D printer. One of the education faculty team members stated, “Once we were finished building the printer I was very proud and excited to think about the possibilities of using this printer in my courses.” Participants reported as well that ways they would share the 3D printer with their colleagues, write a grant for science and literacy makerspace curricula, create 3D printed objects for alumni-related projects, as well as work with faculty in foundation courses to incorporate 3D printing.

At the conclusion of the experience, four of the six participants completed building their Jellybox 3D printer and successfully printed 3D objects. Two of the participants were unable to complete the 5-week session and did not build their 3D printer. While we had hoped for all six participants to complete the 3D printer, the results we saw from the four who have completed have been positive.

Two of the participants in the college of education shared that as newer faculty to the university, this program helped them carve out time to work on a project together. This allowed them to establish a working relationship with a colleague that has expanded beyond just building a 3D printer together. As a result of this workshop, these two participants and the two facilitators of the program have formed a collaboration to explore 3D printing in more depth both at the university and in the surrounding pre-K–12 schools. A 3D printing real-world solutions course has now been designed by one of the participants and one of the facilitators to incorporate 3D printing into a general education course.

Two of the participants in the school of media arts and design shared their excitement of having a 3D printer in their department by talking about the types of class projects they plan to implement. One approach they would like to employ is experimenting with 3D printing to create plates/matrices for very old and traditional printing methods, such as relief presses. The team borrowed this idea from Jason Webb, a creative technologist based in Minnesota.

Conclusion

There are barriers—either due to cost or location—to emerging educational technologies making them not immediately available to faculty and students in higher education, and thwarting the opportunity for hands-on experience. However, innovative educational technologies such as 3D printing are already being utilized in engineering and technology-related fields and are increasingly being used in a variety of professions. Makerspaces and other campus technology supports have the potential to provide the opportunity for faculty to develop the skills to incorporate these technologies into disciplines in the humanities and social sciences, as well as to promote collaboration between faculty across disciplines. Innovative programming through libraries for faculty is one way to encourage the adoption of cutting-edge technology but it may not be enough to drive full adoption. While we found that this experience provided insight into potential methods for supporting faculty in adopting these new technologies, and also highlighted challenges that exist in these efforts—as well as how these outcomes can lead to new collaborations—we have also found that there may be better ways to support 3D printing. These include focusing on the instructional design process, offering intensive learning opportunities to design new assignments for specific disciplines, and also offering opportunities to share work on the academic stage through the development of a new academic conference to showcase curriculum design and research.